Balance Your Project Portfolio Between Current Needs and Future Goals

Project and portfolio management revolve around orchestrating efforts that are launching or are in progress, as well as planning for future initiatives. The efforts that

Project and portfolio management revolve around orchestrating efforts that are launching or are in progress, as well as planning for future initiatives. The efforts that

Time is an important component in every project. From scheduling sought-after craft labor resources to meeting key task deadlines, PMs must remain focused on time throughout the effort. But some projects are more time-sensitive than others. If your team is working on initiatives that require tight timeframes or have fixed completion dates, keep these helpful strategies.

One common problem organizations encounter is the existence of multiple concurrent plans for a single project. Between the various cross-functional groups, from accounting to engineering to HR, you may discover there are too many schedules in use. With all these timetables floating around, how can you trust any of the resulting progress estimates? The true status of each activity soon becomes a big question mark. Sound familiar? It’s the “many truths” problem and it could doom your project to failure.

Planning and executing a facility shutdown project is a complex effort. A wide range of tasks must be carefully sequenced to ensure operations continue as long as necessary, and the rest of the organization should be shielded as much as possible from any of the closures negative downstream effects.

With numerous stakeholders to support and ambitious corporate goals to achieve, project teams sometimes fall into the trap of over-committing themselves as they try to make everyone happy. Some agree to aggressive schedules in hopes they can shave time off along the way. Others begin projects with a too-lean budget expecting they will somehow keep expenditures below normal levels. In each case, the team usually ends up looking bad in the end, as the project’s target completion date encounters delays and requests for additional funds pile up.

Several factors can create challenges for manufacturing project teams. For example, among the many concerns for PMs today are unexpected supply chain issues related to ramping up after a prolonged downturn. It can be tremendously difficult to juggle increased manufacturing needs—often with time pressures as primary drivers—against potentially decreased bandwidth across suppliers and producers.

Gaining cooperation across disparate sub-groups is sometimes a difficult task for project managers. Even when everyone agrees they’re on the same page and working toward the same goals, it’s not uncommon to discover that communication channels between the groups are weak and collaboration is lacking. Some departments may have a tough time fully engaging with the effort. Others might try to push their opinions and preferences to the forefront. Participation in meetings and brainstorming sessions is often hit or miss.

Ongoing education is a critical part of maintaining a Project Team’s base of skills and expertise. Using internal team members to train others in the group is often an attractive option—it doesn’t entail the typical hard costs associated with outside training and classes can be conducted with little advance planning. This takes good advantage of downtime while keeping everyone up to date on best practices. However, though the cost savings and flexibility may be tempting, there are some challenges that teams need to be mindful of if they want to get the most benefit out of their internal training opportunities.

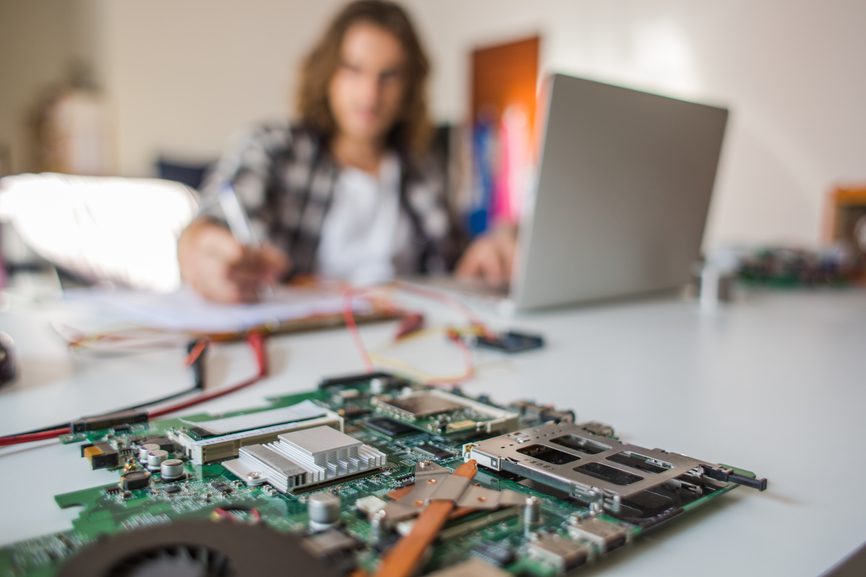

In addition to the challenges project managers commonly face, initiatives that revolve around technology—upgrades, expansions, system replacements, etc.—bring their own unique obstacles. These can be especially difficult to navigate when you’re trying to execute a technology-related project in a non-technology organization. If a project that’s heavy on technology is on the horizon for your team, consider where roadblocks are likely to exist and the strategies that can help you overcome them.

The ongoing economic uncertainty —what its impacts will be in the marketplace and when those effects will be felt—has many companies considering where they may

We partner with our clients to provide mission-critical project management solutions.

Corporate Headquarters

3355 Lenox Road

Suite 750

Atlanta, GA 30326

Toll-free (US): 866.808.3735

International: +1.770.938.4947

Fax: 770.234.6997

PMP, PMI, PMBOK, CAPM are registered marks of the Project Management Institute, Inc.

We use cookies to enhance your browsing experience, analyze site traffic, and personalize content. By continuing to use our site, you consent to our use of cookies.